Advanced Shot Blasting Equipment Solutions

Industrial shot blasting machines and automated surface preparation systems designed for heavy-duty metal cleaning, scale removal, and surface profiling. Our precision equipment delivers consistent results for automotive, aerospace, and manufacturing applications worldwide.

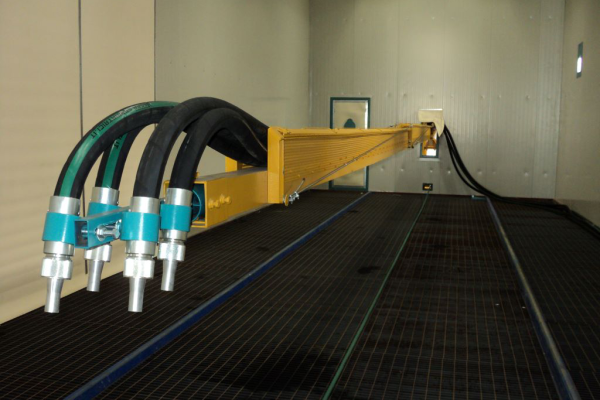

Complete Industrial Blast Room Systems

Custom-engineered blast rooms and sandblasting facilities for large-scale surface treatment projects. From steel structure preparation to heavy equipment restoration, our blast room solutions provide efficient abrasive blasting capabilities with advanced dust collection and safety features

Compressed Air & Metallizing Solutions

Professional compressed air systems and thermal spray metallizing equipment for precision surface coating applications. Our integrated solutions support powder coating, metal spraying, and specialized surface treatment processes in aerospace, marine, and industrial manufacturing sectors.

Shot peening machine

Our industrial surface treatment equipment including shot blasting machines, powder coating systems, and metallizing solutions optimize metal processing operations for manufacturers globally.

Disa International specializes in industrial surface preparation equipment including blast cabinets, powder coating booths, compressed air systems, and thermal spray metallizing machines.

We provide complete blasting media solutions from steel grit to ceramic beads, backed by three decades of metal surface treatment innovation.

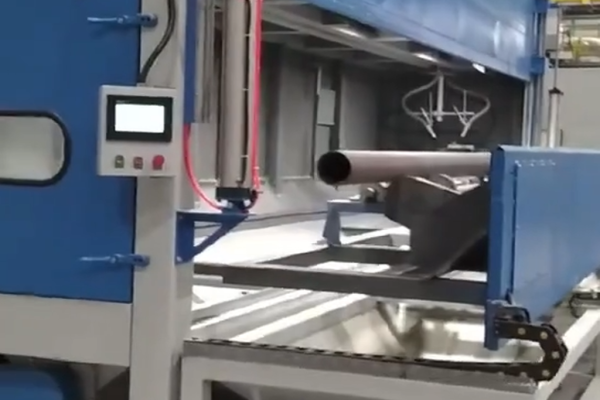

Pipe Internal Blasting Machine

From high-performance shot blasting machines and automated sandblasting systems to complete surface preparation facilities for shipyards, offshore platforms, and industrial coating operations.