- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Professional blast cabinet: industrial quality

Disa blasting cabinets are manufactured using thick steel plates through forming and welding processes. The design of each product emphasizes safety and convenience, aiming to enhance the product’s durability and user-friendliness. The blast gun nozzles and air nozzles are made of tungsten carbide, whose service life is much longer than that of ceramic materials. Features such as full-width openings, protective fluorescent lighting, air safety switches, and air regulators contribute to easily and stably achieving excellent blasting results.

Disa blast cabinets are proven standard blast machines. The cabinets are available with suction or pressure blast system and dust collector. The standard version is characterized by a roll-up front door and a large inspection window.

Leveraging 20 years of experience in the manufacturing of automatic shot blasting systems, Disa is capable of customizing automated blasting cabinets with various configurations according to customers’ specific requirements.

The shot blasting booths are especially designed for manual blast or shot blasting of large parts. The cabins are prepared with ambient exhaust and abrasive recovery equipment so they can be cleaned and reused.The cabin structure is made of modular panels that are easy to assemble.

Automate or expand your blast cabinet for greater efficiency

The production of compressed air-driven, compact blasting systems with a corresponding filter system is the core task and the heart of our company.In the fields of batch shot blasting and shot peening, we focus on developing customer-centric solutions that integrate seamlessly into fully automated manufacturing processes. Our systems feature advanced technologies and strong cost efficiency. Leveraging expertise in shot blasting automation, we offer blast cabinets of various sizes along with material handling systems. Our engineers can demonstrate a full spectrum of processes, from small air blasting operations to large robotic blasting setups. Through customized engineering solutions, we deliver high-quality assurance and cost-effectiveness, giving customers a significant competitive edge.

Disa suction blast cabinet operates based on a vacuum system. In this case, the abrasive media for sandblasting is sucked in by the vacuum generated inside the blast head. Through this method, the mixture of abrasive media and air is sprayed onto the surface of the workpiece via the sandblasting nozzle. In most cases, injection sandblasting uses abrasive media with relatively low specific gravity, such as glass beads or aluminum oxide.The injection blast cabinets are cost-effective, with fewer moving parts. Compared with direct pressure systems, they require less maintenance and can perform continuous blasting operations without pausing to replenish abrasive media.

Disa vacu-blast cabinet comprises two separate free-standing units, a cabinet assembly and an integral pressure feeding generator/reclaimer/dust collector, which together with the blast hose and nozzle assembly form a highly efficient blasting cabinet for abrasive blast cleaning, product finishing and impact treatment.

The pressure blast cabinet adopts a pressure tank, which delivers the media from the tank to the nozzle through the blast hose. The pressure tank container of the direct pressure device has the same pressure. It is connected to the outlet of the abrasive metering valve via an air pipeline. This process has a blasting power that is many times higher than the injector blasting principle and is mainly used in abrasive blasting on blasting systems that are designed for high performance (paint stripping, rust removal, descaling).

Standard injection and pressure blast cabinets

Injector blasting and pressrre cabins are ideally suited for blasting a large number of smaller workpieces. The systems can be equipped with rotating baskets, turntables, oscillating devices and other special equipment.

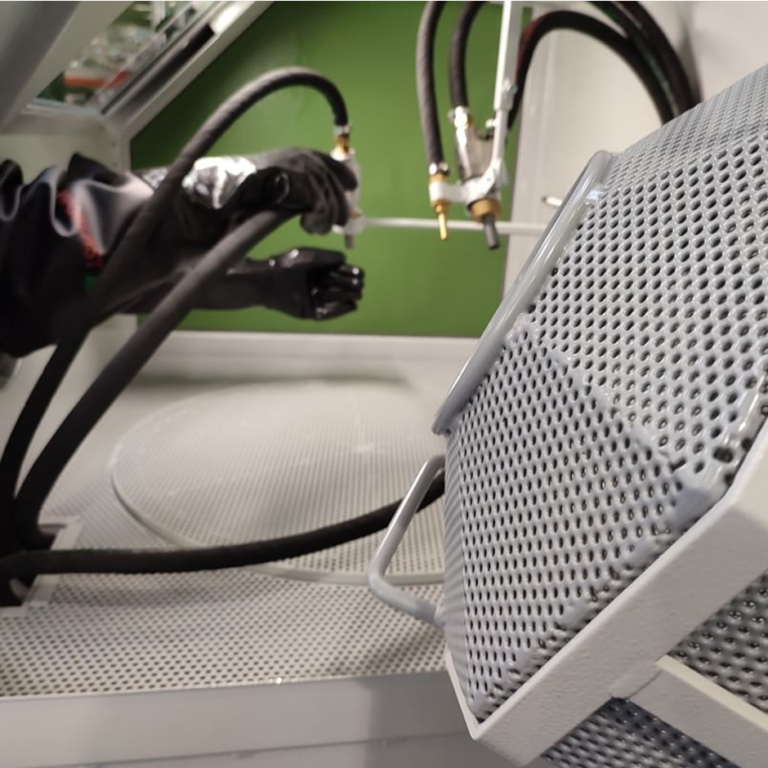

In these machines, the parts are placed inside the cabin and the worker introduces his hands inside the cabin to clean the parts.

These cabins are prepared to work with suction or overpressure systems, depending on the type of work to perform.

These cabins are equipped with the means to recover and select the abrasive material, as well as with filters to eliminate dust from the cabin, so the operator always works in a healthy environment and is protected from impacts by the abrasive.

The cabins can be equipped with loading and unloading elements, accessories, roller tables and removable tables in the event of heavy parts.

The tumble belt blasting cabinet is ideal for batch processing of high-volume production parts made from a variety of different materials. It can handle small, precision thermosetting plastic parts, and is used for sand removal, descaling, rust removal, deburring, and achieving a uniform surface finish. A variety of mineral-based and highly abrasive shot blasting media can be used with it.

The blasting cabinet is equipped with a turntable, and a variety of turntables with different sizes and load-bearing capacities are available for selection. The turntable can be rotated either manually or by an electric motor. Partial automation can be achieved through the movement (in horizontal/vertical directions) of a mechanical/pneumatic sandblasting gun.

The rotary basket blasting cabinet can perform shot peening on entire batches of small workpieces, and the workpieces can tumble against each other during the treatment process. The basket can be easily placed into the star-shaped tiltable fixture. Its rotation is driven by an electric motor located outside the cabinet. The continuous tumbling of the workpieces in the rotary basket ensures a uniform and optimal shot blasting effect.

Continuous roller conveyor blasting cabinets are mainly used for cleaning as well as paint and coating removal in continuous flow operations. They are highly suitable for processing large quantities of workpieces in continuous production lines. The transfer of workpieces is hardly interrupted by loading and unloading. blas guns are installed above the roller conveyor. The oscillation of the blast guns ensures perfect projection coverage across the entire width of the roller conveyor.

A special blast lance, mounted on the cabin wall, allows the blasting of the internal surface of the work pieces. The blast lance movement is controlled by a separate axis. If needed, it can be coordinated with the movements of the robot.

The cabinet can be equipped with a through-feed system transporting the work pieces through the machine, for example, a conveyor belt. This allows continuous flow operation. The blast guns are placed above the through-feed transport system.

The satellite table shot blasting machine is used for continuous processing of precision workpieces, which must not come into contact with each other during the shot blasting process. This type of machine is particularly suitable for shot blasting precisely positioned surface areas.

The application range of this machine spans from casting cleaning to precision shot peening of shafts and transmission components. A workstation is installed on each side of the two operating doors, and each workstation is equipped with one or more satellite tables. This allows one batch of workpieces to undergo loading and unloading operations while another batch is being processed. Since loading/unloading and sandblasting operations can be carried out simultaneously, non-productive time is minimized.

Inside the blast chamber of a automated Robotic blast finishing system,component surfaces are treated via the impact of media—either angular or spherical particles—propelled through precisely positioned, adjustable pneumatic blasting guns and nozzles. The Rotary Spindle Blast Multiblast machine facilitates continuous, selective, or full-surface treatment and finishing of high-volume manufactured components. By rotating the components in front of the robotic arm-mounted blasting guns, not only is a consistently high-quality surface finish achieved, but high productivity is also ensured.

How does a suction blast cabinet work?

The Disa suction blast cabinet offers high cost performance, with fewer moving parts and lower maintenance costs compared to pressure blast systems.

It can operate continuously without stopping to replenish abrasive. Although production efficiency is slightly lower than pressure systems, the final processed surface quality is comparable. For applications prioritizing initial purchase and maintenance costs, this equipment is an ideal choice.

Working Principle Overview:

The abrasive in the hopper is delivered to the gun via a hose.

Regulated compressed air enters the gun through a hose.

Air flows through the air nozzle and enters the mixing chamber and blast nozzle.

The mixing chamber generates negative pressure (suction), drawing the abrasive into the blast nozzle (similar to sucking water through a straw).Compressed air propels the abrasive for acceleration (at a flow rate of approximately 60-100 CFM).

The compressed air consumption (CFM) required to drive the gun is jointly determined by the diameters of the air nozzle and blast nozzle.Equipment Configuration Suggestions:

Disa suction blast equipment comes in various specifications. To enhance efficiency and convenience, pairing with optional accessories (such as the abrasive recycling system recommended when using recyclable abrasives) is often a wise choice. This system saves on abrasive consumption and typically allows for quick cost recovery.

How does a pressure blast cabinet work?

The pressure blast system employs a pressure pot. After the pot is filled with abrasive and pressurized, the abrasive is accelerated and conveyed directly to the nozzle through the blast hose.

In pressure blast equipment, the pressure inside the pressure pot and within the air line connected to the outlet of the abrasive metering valve remains consistent.

Pressure blast systems are also referred to as gravity-fed or isobaric equipment. Abrasives “freely flow” into the airstream under gravitational force, while operators can better control and regulate the blasting process within high or low pressure ranges.

In most application scenarios, due to its significantly higher abrasive conveyance speed, pressure blast equipment offers operational efficiency up to four times that of suction blast cabinets (providing higher throughput capacity per unit time).

Why choose Disa blast cabinets?

Disa blast cabinets are manufactured from thick steel plate through forming and welding processes. The design of each product focuses on safety and ease of use, aiming to enhance durability and user-friendliness. The blast nozzle and air nozzle are made from tungsten carbide, offering a significantly longer lifespan than ceramic materials. Features such as full-width openings, protective fluorescent lighting, air safety switches, and air regulators facilitate consistent and effortless achievement of superior blasting results.

With a diverse range of standard cabinet sizes, design configurations, optional setups, and the ability to customize special systems, Disa can meet the requirements of nearly every customer. Disa’s product line also includes portable pressure blast equipment, various blasting media, and a comprehensive inventory of maintenance parts.

Beyond the complete product range, Disa boasts a knowledgeable technical service team to assist you in selecting the right equipment and media for your needs, ensuring your system operates without interruptions.

Disa is committed to providing customers with the highest quality products and services, with its success measured exclusively by customer satisfaction.