- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

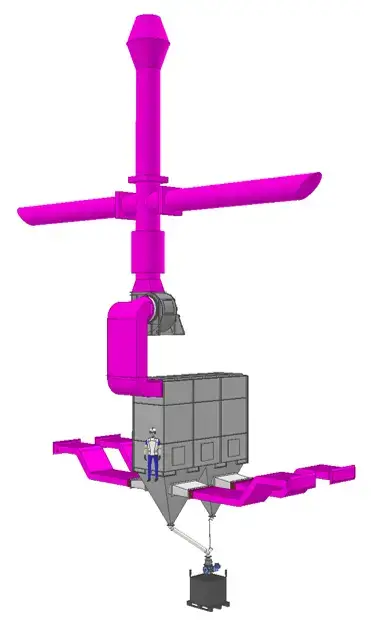

Extraction installation for large blast halls

The steel process generates a lot of dust, which makes it impossible to have a good view of the work. This dust will also overload the abrasive cleaner. The result is a blasting medium which contains excessive dust and will cause unnecessary wear to the installation. In addition, the large blasting hall will become unacceptably heavy, which will not benefit the quality of the final coating on the workpiece.

Cartridge filter

In recent years, Straaltechniek International has been applying more and more cartridge filters, also in these types of large blast halls. Check out this reference for more information on these types of filters!

Due to the construction of the SMT hose filter, it can be perfectly integrated into the steel construction of the large blasting hall; therefore, it is very easily accessible for inspection and maintenance.

The filter is often built into the 1st floor, so that the dust funnels protrude through the floor and the dust can easily be discharged through a pipe to an easily accessible place on the ground floor for a forklift truck.

The polyester needle filter hoses are suspended from a flexible shaking frame. The hoses are provided with a click ring at the bottom. The hose is fixed by means of the click ring in a round recess in the bottom of the filter.

The SMKT filter each has a maximum of 196 filter hoses, this way an enormous capacity is created.

The dust-polluted air from the blasting space is drawn through the filter hoses via the suction tube. This air flow goes through the inside to the outside of the filter hose and is discharged at the top of the filter. This way, the dust remains on the inside of the filter hose.

At pre-set times, a PLC (programmable logic controller) activates the imbalance motors on the shaker window. Due to the vibrations, the dust is shaken off the filter surface and goes via the dust discharge funnel to a big bag. This way, the filter hoses are cleaned and are ready for use again.

Reference pictures

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).