- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

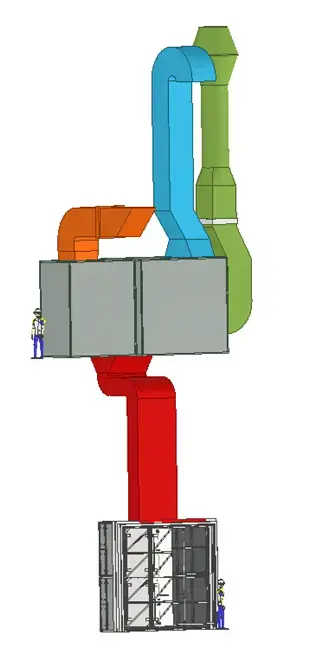

Spray installation big hall

The spraying in the combi-hall consists, just like in a normal spray booth, of:

- Preheat

- Spraying

- Drying

The enormous dimensions of the combi halls, 20,000 m3 is no exception. Naturally, it requires a substantial air treatment installation. Although the dimensions are very large, the basis is, and will remain to use the physical principles with the Mollier diagram as an important tool.

The air treatment installation usually consists of:

- Heating appliance

- Dehumidifiers (air dryer)

Paint mist walls are provided to catch the paint mist during spraying.

The doors of the paint mist wall were opened during spraying. The paint mist is collected by means of a paper Andreae filter and a paint stop filter. A fan in the heating appliance extracts the filtered air through the red channel. The filtered air is fed into the heating appliance through a heat exchanger and then blows out through the green exhaust duct.

A second fan in the heating appliance draws fresh air from outside the building. This air is preheated by the heat exchanger which is heated by the extracted filtered air. This air is then passed along a burner or second heat exchanger. The heated air is then blown into the Combi hall and ensures that the correct paint processing temperature prevails in the Combi hall.

Both air flows in the heating appliance are separated from each other. During drying, to save energy, the extracted air from the Combi hall can be partially recirculated (80-85%).

The extraction boxes type AZW (each 4 x 4 meters) consist of a closed anodized aluminum frame with galvanized steel panels. The filter, type HE + Andreae, retains the paint mist with an efficiency of 99.81%. The extraction boxes are protected by protective doors during blasting.

View these real-life examples

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).