- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Pressure fed blast cabinet

A professional hand blast cabinet for roughening, cleaning, rust removal, matting, deburring and polishing of workpieces. An installation that is suitable for all types of blasting media.

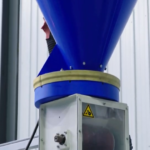

The pressure blast cabinet is equipped with a cyclone separator. The cyclone separates the reusable abrasive and the resulting dust. The supply of the abrasive takes place in a closed circuit and the amount of abrasive is adjustable. By using the most modern type Straalmeester® pressure blast boiler, type 2000, equipped with a pneumatically controlled grit dosing valve, you are assured of an accurate adjustment of the blasting medium, as well as the possibility to blow off the blasted workpieces with air only.

PRESSURE FED BLAST CABINET DS125SR

The standard pressure fed blast cabinet comprises two separate free-standing units, a cabinet assembly and an integral pressure feeding generator/reclaimer/dust collector, which together with the blast hose and nozzle assembly form a highly efficient blasting cabinet for abrasive blast cleaning, product finishing and impact treatment.

- 2 Entrance doors with security on both doors

- Fluorescent lighting 2 x 18 Watt

- Continuously cleaning cartridge filter (integrated)

VIEWING WINDOW

Visibility within the cabinet is optimized by the provision of a large viewing window 717 mm wide by 387 mm deep. The window can be further protected if needed (please ask regarding cost) by a replaceable gauze to reduce risk of damage, and to increase the usable working life of the glass (Option).

OPERATOR ARM HOLES

An easily replaceable panel with elliptical apertures fitted with arm

length antistatic rubber gauntlets to help reduce the risk of static shocks for the operator is positioned below the viewing window. This arrangement provides maximum access to the interior during operation with freedom of movement for the operator and prevents spillage of dust and media.

INTERNAL LIGHTING

Illumination within the cabinet is provided by an 18-Watt LED lamp unit mounted centrally in the roof, which provides a lighting level of 750 lux at the work area. A shatterproof visor protects the lamps against damage from deflected media.

DOOR INTERLOCK

An electrical switch is fitted to the door as standard. This ensures that if the door is opened the media blasting is inhibited.

FOOT PEDAL

The standard foot-operated blast control valve (foot pedal) fitted to Ventus machines is provided with a protective shroud to prevent unintentional activation.

PRESSURE REGULATION

Blast pressure is easily adjusted from the operator’s position by using the pressure regulator in conjunction with the pressure gauge. This facility allows the operator to control blast pressure between 0.5 to 7 bar (8 to 100 psi) to suit the application and ensure optimum productivity whilst minimizing abrasive usage and wear to the equipment. Provision is made for the pressure regulator to be locked at a maximum operating pressure to prevent the operator from blasting sensitive components at incorrect blast pressures.

ACCESS DOOR

Work to be processed is loaded into the cabinet through the side-opening freely hinged door that is securely closed during blasting by a roller-action clamp. A unique door seal around the door prevents leakage whilst blasting.

BLOWGUN

A hand-operated blowgun is located inside the cabinet that allows the operator to clean components and the cabinet interior of media when the blast cycle is complete. The blow gun is a simple to operate deflector type.

GENERATOR/ RECLAIMER ASSEMBLY

This comprises a free-standing generator/dust collector unit which may be positioned anywhere within the constraints of the connecting hoses, thus allowing the user to make maximum use of available space for the machine. The vacuum recovery hose is handmade, reinforced and polyurethane lined to give a very long service life.

RECLAIMER SECTION

The reclaimer section incorporates a sophisticated adjustable air wash to ensure highly efficient separation of dust from the re-usable media. The air-wash assembly is suspended vertically down the centre of the reclaimer body. At its bottom end the air-wash tube has an outward/downward directed flange. Inside the conical flange an adjustable cone is positioned to form an annulus between the flange and the cone. In passing through the annulus the airflow carries with it the lighter dust particles suspended in the recovery airflow, whilst the heavier particles gravitate to the storage hopper. The velocity and volume of air passing through the annulus therefore determines the amount and size of the dust particles conveyed upward through the air-wash tube. Material leaving the base of the reclaimer cyclone falls into an integral storage and feed unit.

BLAST POT

The bottom of the storage hopper is fitted with a flange from which the pressure vessel is suspended. The pressure vessel is of a large 42L gross capacity and is equipped with an internally mounted dump valve at the top and an externally mounted media feed valve at the bottom.

The dump valve is closed whilst blasting is in process and opens automatically to allow transfer of the media from the storage hopper whenever the blast control valve is switched off.

BLAST NOZZLE

A 6.4mm diameter, long-life BORON CARBIDE lined nozzle is supplied with the machine. An alternative tungsten carbide lined nozzle is available for use with ferrous abrasive.

FEED VALVE

The feed valve accurately meters the quantity of media entering the blast stream that then passes through the blast hose to the blast nozzle. The feed valve is fully adjustable to suit a wide range of media sizes and incorporates media aeration to fluidise the abrasive and ensure the accurate metering of fine non-metallic abrasives.

AIR CONTROL SYSTEM

A modular type pneumatic control system incorporating push-in connectors for ease of maintenance is utilised. The system incorporates a manual shut-off valve, a moisture extractor that removes water in globular form, a pilot operated pressure regulator and a three-way control valve.

DUST COLLECTOR

The dust collector is attached to the power pack, this minimises the floor space requirement. It provides a high airflow for recovering dust and fine debris released in the cabinet during blasting. It consists of three high performance cartridge filter elements ensuring a high-quality filtration complete with a reverse jet pulse cleaning system that is operated at the start of each blast cycle.

The filter elements are easily accessed for maintenance via a large inspection door in the maintenance friendly clean side of the dust collector, secured by easily removed hand-tightened fitments. The cartridges are retained by quickly detachable clamps and sealing rings.

A dust container – easily removable for dust disposal – is mounted beneath the filter element to collect separated dust. The airflow is generated by an electric motor driven centrifugal fan mounted directly above the filter housing. A direct on-line starter is included which is mounted above the dust collector on the left-hand side.

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).