- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Smart reclaim of abrasive

A media conveyor system is an essential part of a total abrasive recycling system. During the blasting work, the used blasting medium falls on the floor of the blast cabinet. The abrasive must be regularly brought to the storage silo so that the blasting vessel can be supplied with sufficient abrasive at any time. The blasting media recovery installation ensures that the blasting media is returned to the silo.

Straaltechniek International supplies various solutions, varying from horizontal and vertical transport to systems with integrated dust extraction.

Options for the floor of the cabin

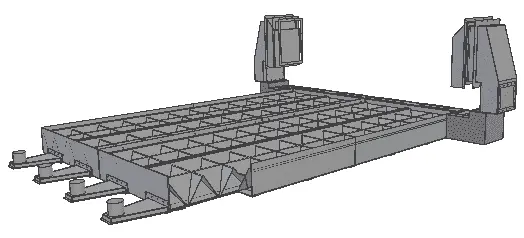

Scraper

The long scraper tracks are equipped with rubber scraper flaps, which push the abrasive in the direction of the cross conveyance. The cross transport then takes the abrasive to the elevator outside the blast cabinet. The cross transport also consists of a scraper or screw conveyor. This comes out in the bottom part of the elevator.

This is the solution for large and smaller cabins, with high required productivity.

Pros and cons:

- Shallow foundation as compared with a screw or conveyor belt

- Most user-friendly

- A relatively cheap solution per square meter compared to man hours

- Foundation shallow, but over the entire cabin surface

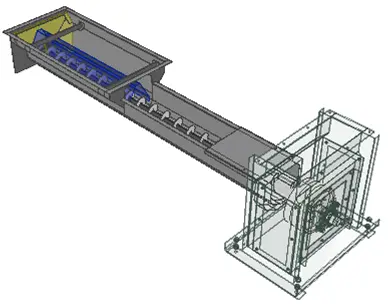

Screw conveyor - Type 4A0

Screw conveyor can be used to bring the abrasive to the base of the elevator. A transverse screw conveyor is usually located at the end of the blast cabin and lower than the longitudinal screw conveyors. Screws (almost always) come with funnels, so that abrasive is automatically collected over a larger area.

The short screw conveyor is placed in a steel gutter and covered by a dosing plate. At floor level, the gutter is covered with grating topped with a perforated plate that prevents larger parts from ending up in the transport.

The abrasive is collected manually and discharged to the cross conveyor, by sweeping at regular intervals with a shovel, brush or broom. The cross transport then takes the abrasive to the elevator outside the blast cabinet. The cross transport consists of a short screw type 4A0.

- Cross screw 4A0

- Elevator

- Cleaner (/ shaking sieve)

- Silo

Pros and cons:

- Very robust and easy to maintain

- High capacity

- Can also be placed on the floor

- Foundation necessary for a flat floor

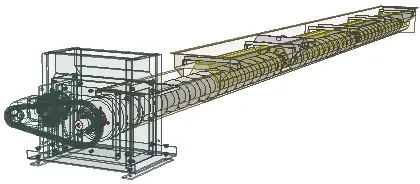

Screw Conveyor - Type 4A1

The long screw conveyor is placed in a steel gutter and covered by a dosing plate. At floor level, the gutter is covered with grating topped with a perforated plate that prevents larger parts from ending up in the transport.

The abrasive is collected manually and discharged to the cross conveyor, by sweeping at regular intervals with a shovel, brush or broom. The cross transport then takes the abrasive to the elevator outside the blast cabinet. The cross transport consists of a long screw type 4A1.

- Cross screw 4A1

- Elevator

- Cleaner (/ shaking sieve)

- Silo

Pros and cons:

- Very robust and easy to maintain

- High capacity

- Foundation necessary

Venti-floor

A combination of the conveying and dust extraction is the Straaltechniek International Ventifloor system. The blasting medium, dirt and dust are discharged through the cabin floor by means of an under-pressure and separated from each other by a cyclone.

Pros and cons:

- All abrasive including dust and dirt is fully automatically recovered from the cabin and transported to the cleaner

- Very user-friendly

- A relatively expensive solution per square meter

- Foundation shallow, but over the entire cabin surface

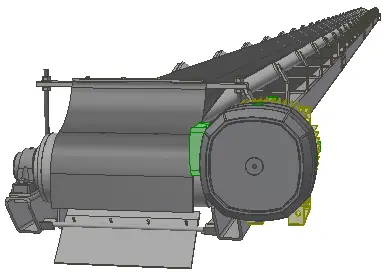

Belt transport

Conveyor system in which the abrasive is pushed into a belt conveyor and then brought to the base of the elevator. The belt conveyor is equipped with funnels with a built-in dosing device, to prevent overloading or blasting. Finally: grating is placed on the funnels above the belt conveyor.

In large booths or cabins, the abrasive that falls to the ground is not transported with a scraper or screw, but with belt transport.

Pros and cons:

- The cheapest solution for large cabins

- Dust development when sweeping in the abrasive on top of the rolling belt

Summarized

There you go Now you have a good feeling about what is possible with regard to our cabin floors. Each customer has its own specific wishes or considerations. You too? Our consultants are ready to answer your questions by phone, via email or WhatsApp (button below). Or go back to the overview!