- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

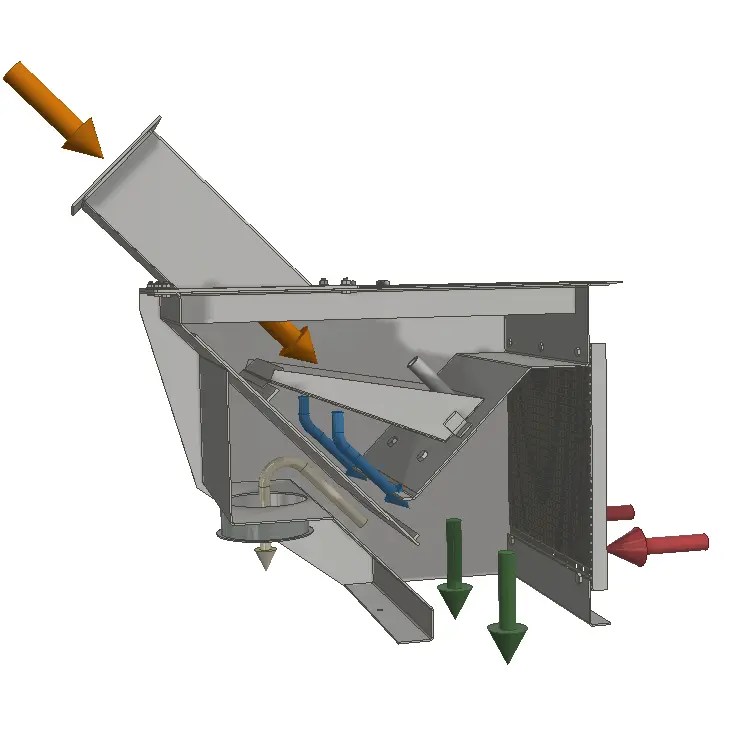

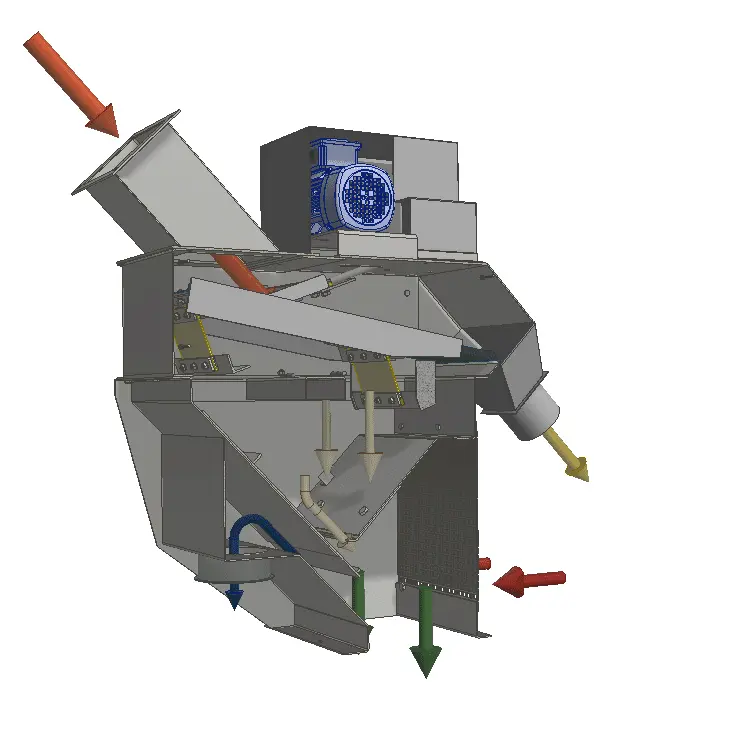

Cleaner

The elevator pours the abrasive into the cleaner. The large contaminants are stopped by a permanently installed but removable sieve. Subsequently, the abrasive is collected behind a distribution valve and distributed as much as possible over the width of the cleaner. The abrasive then falls like a curtain through an air stream and is thus dusted (Windsifter). The cleaned abrasive falls into the silo. The air flow takes the dust to the separate extraction (pre-separator) where it is separated and collected in a dust bag.

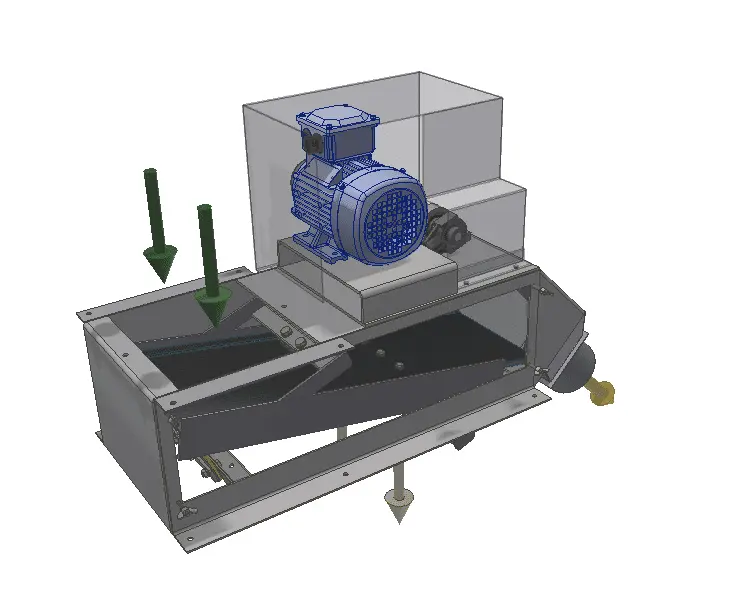

The sieve of the standard cleaner should be emptied regularly. To prevent this, the standard cleaner can be equipped with a shaking sieve. This is placed on top of the cleaner. The abrasive is then ejected by the elevator above this screen. The sieve is mounted slightly inclined on leaf springs and is shaken back and forth. The drive can be done by a shaking motor or by a motor with belt transmission and eccentric shaft. The abrasive falls through the sieve and the larger parts are discharged from the front via a hose to a waste bag.

This combines both of the above solutions.

High-End solution for separating your abrasive

This system is used to separate magnetizable blasting media (e.g. steel, cast iron) from non-magnetizable blasting media (e.g. corundum, glass, ceramic). The separation system includes a motor-driven drum magnet and a demagnetizing unit to remove magnetism from the metallic steel blasting medium.