- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Which blasting methods are available?

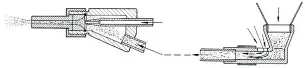

Injection blasting

The injection system takes its name from the injector located in the jet gun. As soon as the compressed air starts to flow via the compressed air hose through the injector of the jet gun a negative pressure is created. As a result, blasting media is sucked in from the funnel, via a “discharge cup”. In the injector chamber, the drawn-in blasting media is mixed with the stream of compressed air. Via the nozzle of the blasting gun the blasting media travel at great speed to the surface to be blasted.

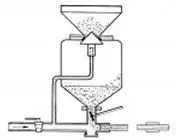

Compressed air blasting

With compressed air blasting, a vessel of air and blasting medium are simultaneously pressurized and added to the air flow. This is a slightly more expensive solution, because of the vessel and some additional control valves and valves are required. Blasting medium falls into the compressed air flow by its own specific weight and is transported to the nozzle, where it is aimed at the product to blast the product. A main valve, filling cone, venting valve, blasting media valve and pump valve are present in the system.

Comparison

With compressed air blasting, a relatively larger blasting media can be used for blasting with less air consumption. The efficiency of a compressed air system is higher, because a lot of energy is lost in an injection system when sucking in the blasting medium. In general it can be said that injection (or injector) systems are only used in case of:

- Very thin material thicknesses

- Relatively low production numbers are required

- Only very limited contaminants are present on the surface.

- If investments have to be made for very limited costs

Main PRO’s and CON’s of injection blasting vs compressed air blasting:

Main PRO’s and CON’s of injection blasting vs compressed air blasting:

| PRO | CON |

|---|---|

| Small and easy to operate equipment | Not suitable for all blasting media. (e.g. cast iron and steel or with a larger grain) |

| Rather low production numbers | Not suitable for removing mill scale, thick rust or paint layers |

| Lower sensitivity to moist compressed air |

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).