- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

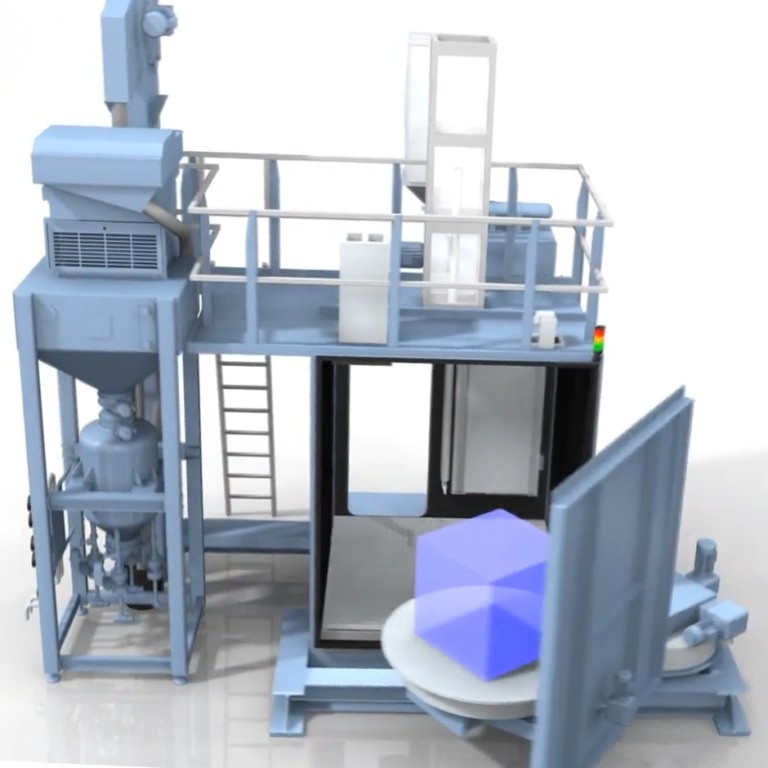

- Satellite table machine

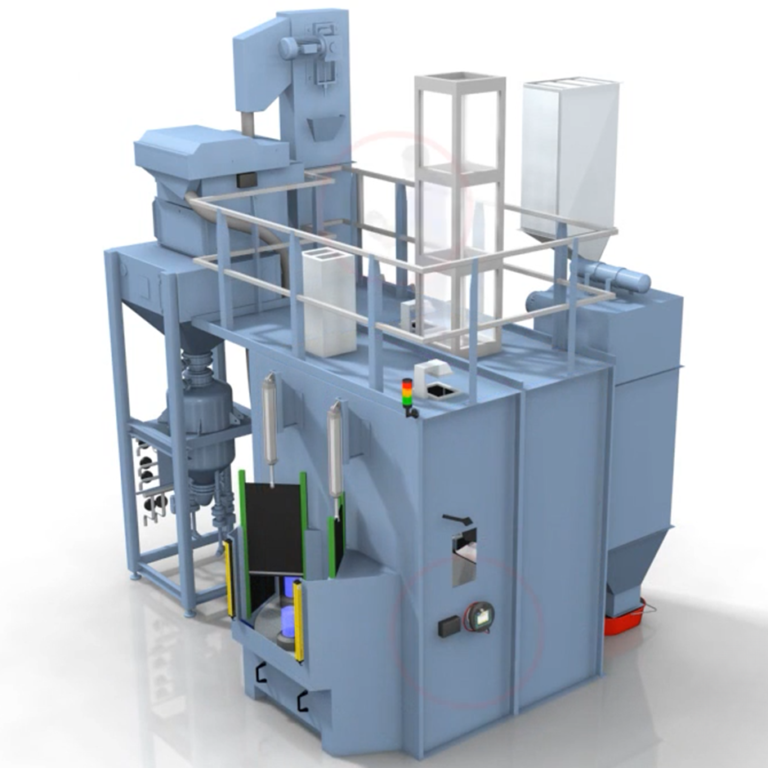

- Blasting installation with sliding door

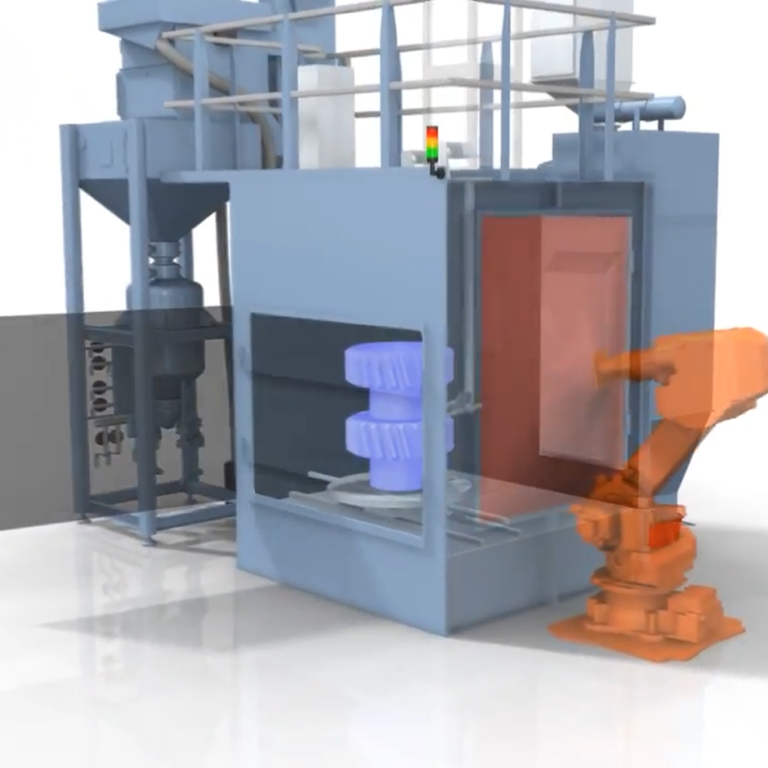

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Contact us for more machines

Ask our experts for more information on shot blasting and sandblasting machines. We are at your disposal to provide you with any clarification on the products and assistance services of our company.

- (86)-0532-88136558

- (86)-135-8923-8091

- info@shotblastingmachines.cn

Service & Support

Leave your details below and one of our specialists will be in touch as soon as possible.

Various configurations of cabinets

Inside the sandblasting chamber, the rotating workpiece is blasted with abrasives from strategically positioned spray guns. The guns are mounted on a multi-axis overhead gantry, moving vertically on linear bearings. Nozzle angles are programmable, with robot control integration possible.

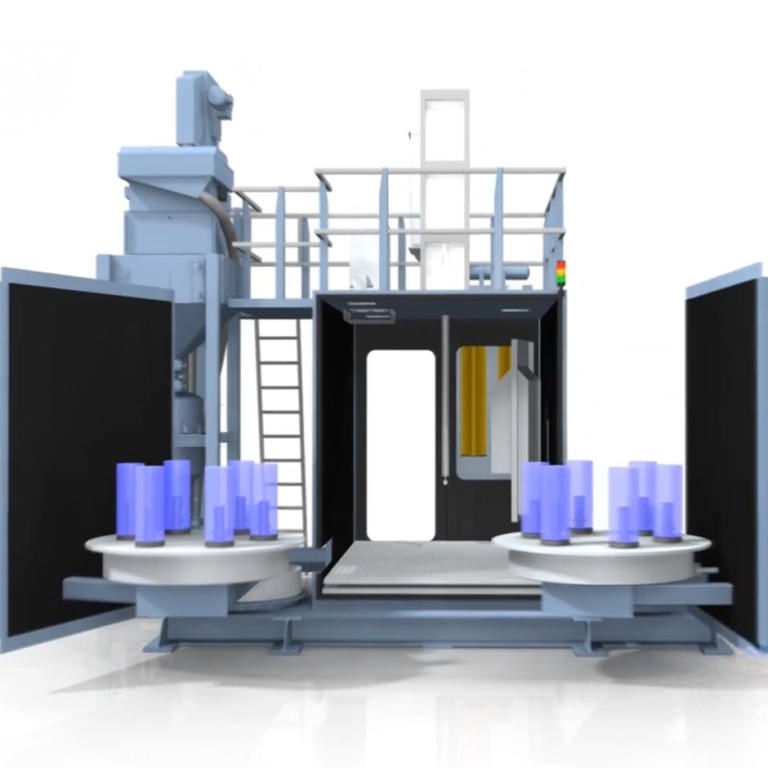

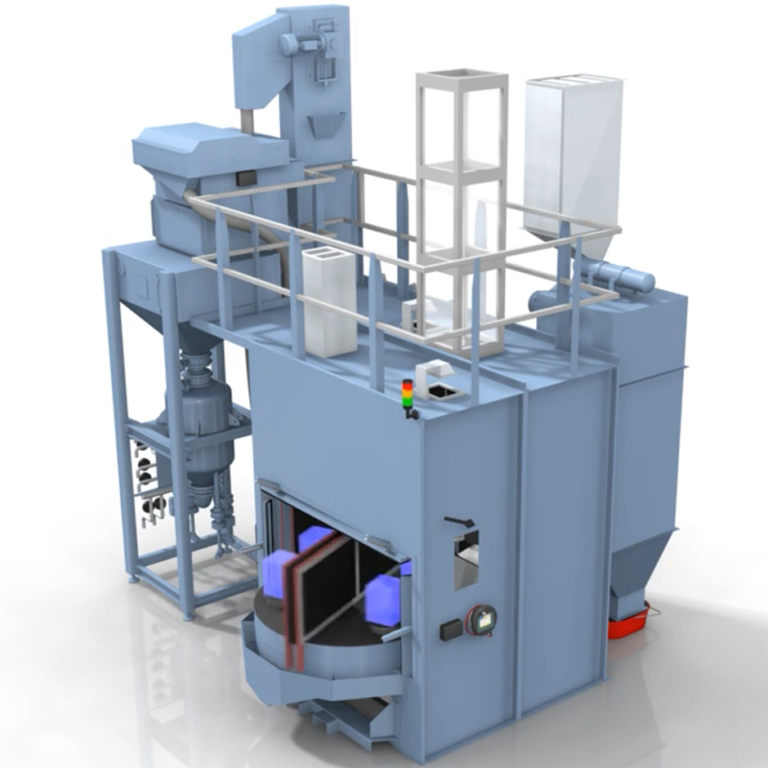

Disa turntable shot peening machine with one or two swing-in turntables at the front of the blasting cabinet. This significantly reduces processing times and the space requirement for the machine.

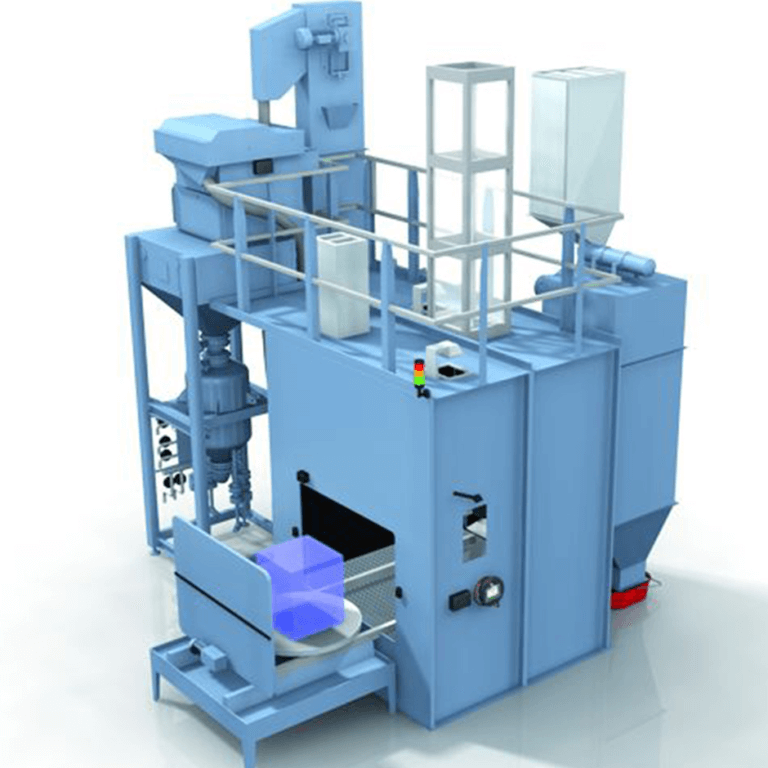

The rotary worktable is equipped with multiple stations, The multiple stations enable the loading and unloading of the processed parts while shot peening the parts, thus maximizing the production output.

One or more worktables will be installed on the main front door of the sandblasting chamber to fix the components to be processed, which greatly reduces the processing time and the space occupied by the equipment. The maximum load of each turntable is 500kg.

The rotary worktable is equipped with multiple stations, The multiple stations enable the loading and unloading of the processed parts while shot peening the parts, thus maximizing the production output.

Table sand blast machine features an optimized working height design for easy loading and unloading. Its roll-in turntable supports lifting by a hall crane, and the satellite fixtures can be adapted to the customer’s fixing system. The workpiece is equipped with rotation and precise angle positioning functions.

Questions?

If you have any questions, don’t hesitate to reach out to one of our shot peening specialists.