- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Closed loop control

Media flow as well as compressed air settings are closed loop controlled. This ensures that these two of the utmost critical parameters are closely monitored and, more important, automatically adjusted within the set tolerances.

The HMI full colour touch screen control panel provides all programming features and visualisation of all set- and actual peening parameters. Different menus can be selected to enable the operator to overview the entire process data. The touch screen control panel is compact and can be either wall mounted or standing on the floor. The USB interface or direct network connection facilitates data transmission.

| Model | Flow Rate Range |

|---|---|

| 576-24 | 0.1 – 1 kg/min |

| 577-24 | 0.45 – 4.5 kg/min |

| 578-24 | 1.4 – 13.5 kg/min |

| 579-24 | 4.5 – 45 kg/min |

| 580-24 | 9 – 90 kg/min |

| 590-24 | 13.6 – 136 kg/min |

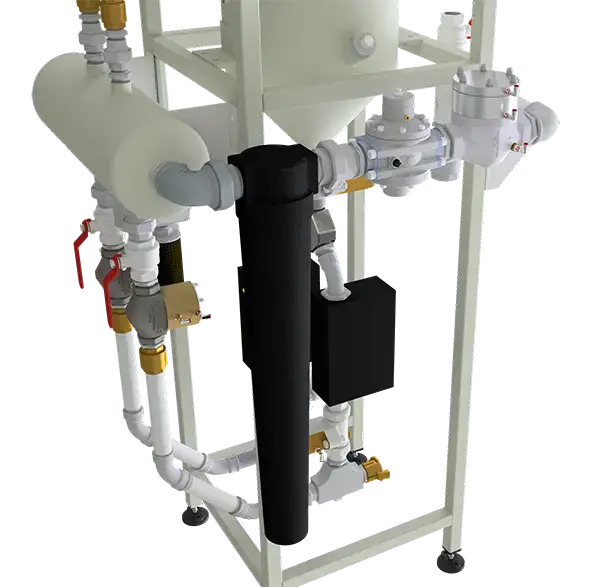

Control and monitoring of the media flow rate is done by using a MagnaValves® and is a closed-loop process. This Magna valve is a normally closed magnetic valve and includes a built-in sensor for accurate measurement of flow rate. Used with our specially developed closed-loop software (no separate controller needed), the Magna valve will provide accurate and repeatable flow rates.

The valve construction includes a permanent magnet for normally closed operation and an electromagnet for controlling media flow rates. By regulating the voltage to the electromagnet, any desired flow rate may be achieved. When power is off, the valve will hold the media due to the permanent magnet.

To guarantee the media flow is within the minimum and maximum limits, alarm scales can be adjusted on the operator screen in the central switch board e.g. 5% deviation gives a visual alarm and 10% deviation is shutdown of application.

Meets SAE AMS 2430 and 2432 specifications.

The 700-24 MagnaValve® is a normally closed valve that regulates the flow of non-ferrous media. The MagnaValve’s built-in sensor measures flow rate and, together with our specially developed software (no separate controller needed) provides accurate and repeatable flow rates. Ceramic bead and glass bead can be used in this valve. Other non-ferrous materials, such as Aluminum Oxide (AlOx), may also be used by special arrangement.

To guarantee the media flow is within the minimum and maximum limits, alarm scales can be adjusted on the operator screen in the central switch board e.g. 5% deviation gives a visual alarm and 10% deviation is shutdown of application.

Meets SAE AMS 2430 and 2432 specifications.

The air pressure (= working pressure) can be adjusted on the HMI operator screen. This operator screen is connected to the main proportional electronic controlled reducing valve. This valve adjusts and monitors the air flow rate continuously.

To guarantee the air pressure is within the minimum and maximum limits, alarm scales can be adjusted on the operator screen in the central switch board e.g. 5% deviation gives a visual alarm and 10% deviation is shutdown of application.

Questions?

If you have any questions, don’t hesitate to reach out to one of our shot peening specialists.