- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Part handling by gear tables and satellites

Various configurations

Various configurations

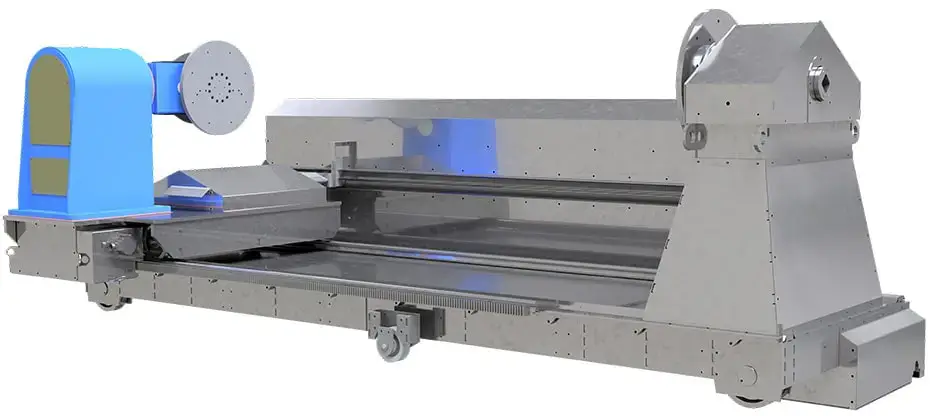

The powered gear table is positioned on a trolley. It is servo-driven for the rotational incremental positioning and full rotation as well as for topple incremental positioning (from 0 – 90°). When the table is in horizontal position, components can be fixed in vertical position. When the table is toppled 90° it can hold and rotate components in horizontal position between the turntable and a tailstock. Both axis of the gear table (rotating- & toppling axis) are interpolating with the arm articulating robot. The gear table will be equipped with a face plate and has a loading capacity of up to 1.000kg.

- Rotating speed of the gear table is free programmable and can be selected on the HMI operator screen

- Both axis of the turntable have the possibility to work as a positioning device with high accuracy

- The face plate is executed with a center locator, threaded holes and T-slots

Opposite to the gear table is a face plate on a tailstock. Components to be peened can be fixed between gear table and faceplate. The powered gear table is positioned on a trolley and is movable to accommodate components of various lengths. The trolley is completed with end stops, to ensure high-accurate positioning of the turntable inside the machine. The trolley with turntable can be moved completely out of the cabinet over precise hardened rails, for easily loading and unloading of parts on the turntable.”

Questions?

If you have any questions, don’t hesitate to reach out to one of our shot peening specialists.