- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@shotblastingmachines.cn

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Classification on size and shape

The elevator provides vertical transport of the abrasive. It consists of a vertical housing with a pulley in the elevator head and a pulley in the elevator base. An endless belt on which steel cups are mounted runs over these pulleys. These cups scoop the abrasive in the elevator foot, transport it to the elevator head and dump the abrasive in the outlet towards the abrasive cleaner.

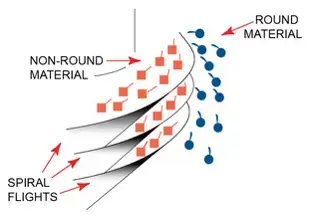

A single- or multicore spiral separator in the bypass separates anything round from anything non-round. The spiral separator operates by gravity and requires no power or maintenance.

View of material flow: Material is loaded into the hopper at the top of the spiral separator. The material then flows over a cone and divides the material evenly onto the inner flights. With increasing speed the round material will separate and roll off the inner flights onto a larger outer flight and then exits a side discharge chute at the bottom and drops into another elevator.

The non-round material on the inner flights will exit a centre discharge chute at the bottom. This material is collected as waste.

The basics start with a 24” two-deck vibratory screen separator assembly to efficiently size and separate the used shot. The vibratory separator receives the media from the reclaim system onto the top-screening surface.

Oversized media and debris are captured on the top screen and are conveyed to a waste container through a duct hose. Reusable and undersized media pass through the top screen to the bottom screen where only the reusable media is captured, separated and conveyed to the storage silo above the double chamber peening machine. Undersized media and fines pass through the bottom screen and are captured on the pan and are conveyed to a waste container through a duct hose.

Questions?

If you have any questions, don’t hesitate to reach out to one of our shot peening specialists.